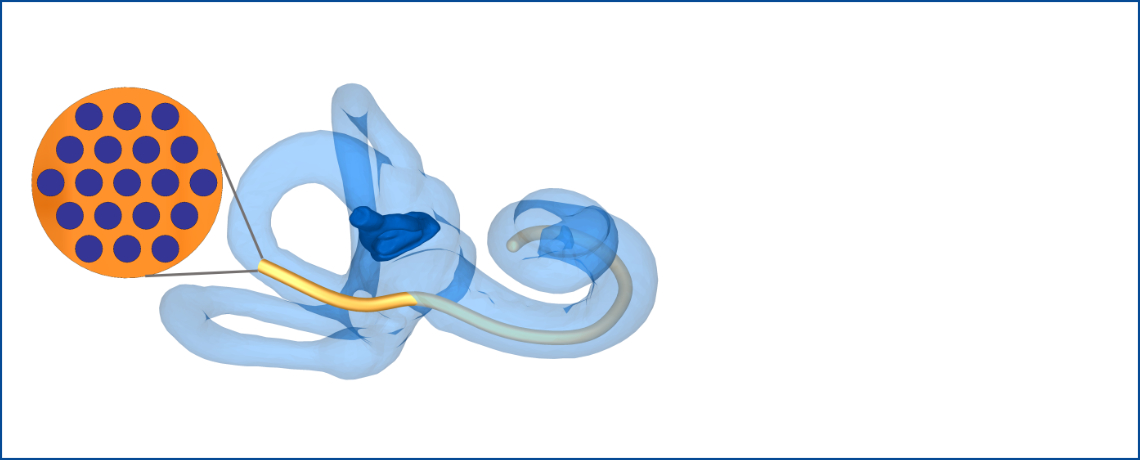

Multiple electrode array for cochlear implants

Medical Need

Today, profound hearing loss and deafness are treated with medical devices, such as cochlear implants (CI). The CI electrode array inserted into the cochlea electrically stimulates the acoustic nerve, which induces auditory perception. Currently, the number of electrodes on the array is limited to less than 30 due to the dimensions of the wires and the manufacturing procedure. Due to the limited number of electrodes it is not possible to sufficiently excite the human auditory region (16 Hz to 20 kHz) with state-of-the-art CI. Cochlear capacities that are important to understand tonal languages or perceive music are not fully exploited. In order to achieve optimal pitch resolution, it is necessary to develop a CI with an increased number of electrodes.

We aim to establish a proof of concept for the development of a next generation textile-based multi-electrode array with up to 100 conductive electrodes as part of an innovative cochlear implant (CI). For this purpose, conjugated filaments are to be woven in a melt spinning process using the island-in-the-sea geometry.

cochlear implant, textile based electrode array, enhanced pitch resolution, melt-spinning technique, island-in-the-sea geometry, matrix fibril type

Project team members

Clinician

TU Dresden, Faculty of Medicine

University Hospital Dresden, Department of Otorhinolaryngology, Head and Neck Surgery, Ear Research Center Dresden (ERCD)

Project team members

High-tech

Technische Universität Dresden,

Institute of Textile Machinery and High Performance Material Technology (ITM)

Abstract

The aim of the project is to provide a proof of concept for an innovative cochlear implant (CI) electrode array consisting of up to 100 conductive electrodes using conjugated filaments (matrix fibril type (M/F)) with the help of an island-in-the-sea geometry through an interdisciplinary collaboration between clinician scientists of the ENT medical speciality and textile research engineers.

Electrically conductive filament yarns are already used in medical devices as textile based sensors to monitor vital parameters (a.e. body temperatures, ventilation) and to detect ions or biomolecules in various body fluids and volatile compounds. Due to their textile character, conductive filament yarns are defined by their good electrical conductivity, oxidation resistance, biocompatibility, yielding, flexibility and resistance to folding, representing a promising alternative to current Pt-Ir metal electrodes. Filaments fabricated by means of bi-component (bico) melt spinning technology with an electrically conductive core (island) and an insulating sheath material (sea) offer the possibility to increase the number of electrodes within the CI electrode array. An increased number of electrodes improves pitch resolution and promotes improved speech perception and intensified music experience.

With a spinning process, a yarn consisting of 37 single M/F filaments with diameters ranging from 65 μm up to 1 mm will be manufactured. The technological challenge is to ensure the required distribution, conductivity and insulation of each individual electrode in the CI electrode array during a single manufacturing step. The exposure of the contact areas towards the Modiolus cochleae is also demanding.

To ensure the functionality of all electrodes, their electrical conductivity and the frequency-dependent current/voltage ratio must be determined. In addition, the surface geometry, the electrode diameter as well as the bending stiffness and the force-strain behavior of the M/F filaments must be comprehensively investigated. The visibility in imaging, the positioning control of the electrode and its contact points are examined by means of digital volume tomography. Temporal bone preparations will be used to test the handling capability of the electrode as well as the force and quality during insertion into the cochlea.